A new bird net winder to wind up and store bird netting mounted on the sides of the vines has been built for Johnston Vineyards.

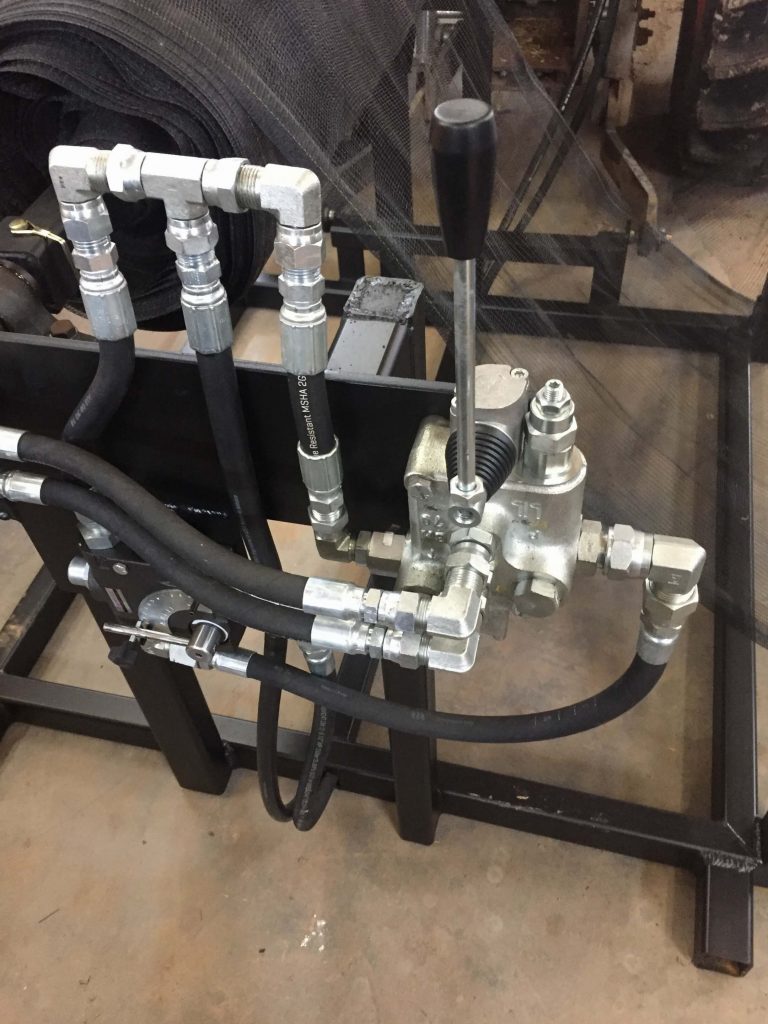

It has an easily accessible external handle to control speed and direction removing the need for an operator to sit in the tractor cab.

There are 6 bars to thread the net through to enable a tight roll. The top bar is rounded to encourage the net to spread out as it enters the 5 lower bars. The central core is a steel bar that is locked and prevents slippage on the roll. It remains with the roll until it is unwound onto the vines next season. This is a 2 man operation. The winder can be easily modified to allow over the row netting to be distributed and wound up. The winder is mounted sideways on the tractor which allows the operator to drive along the end of the rows rather than positioning the winder to face each individual row.

The Kubota ATV has a bar attached to the rear that holds the roll of netting to be applied. The vertically placed central steel core rod rotates as the netting is manually pulled off the roll and is attached to the vine catch wires. A key to added efficiency is to put the netting on in a continuous roll, wrapping around the ends of the rows and laying it on the ground between rows until the roll is completely unwrapped. The roll is not cut. This makes winding the net up for storage much simpler. There is no need to mark to the sections of netting to make sure that the netting fits next year.